Embedded Technologies: Power From the People

Energy harvested from our bodies will make possible mind-boggling gadgetry

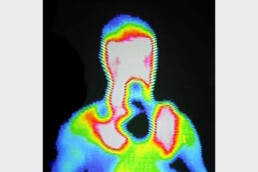

Sensor-studded clothing worn by a soldier tracks his movements and vital signs. A disposable electrocardiogram machine the size of a Band-Aid monitors a heart patient. A cellphone is implanted in a tooth. Scientists and engineers are trying to develop such “embedded” devices: miniature electronics that plug people into computer and communication networks.

Consider contact lenses that function as computer screens. A University of Washington research team, led by electrical engineering professor Babak Parviz, has developed a prototype lens fitted with a tiny radio (for receiving data) and a light-emitting diode, or LED (for displaying data to its wearer). The technology has prompted comparisons to the computer readouts that flash in the eyes of the cyborg in the Terminator films.

Power from motion and vibrations

Forget about batteries. The ability to harness electricity from tiny vibrations could power a new generation of electronic devices.

This is the second of a series about MIT research on harnessing micro-sources of power (part one can be read here).

The Trans-Alaska Pipeline System, which traverses hundreds of miles of some of the most inhospitable terrain on Earth, must be monitored almost constantly for potential problems like corrosion or cracking. Humans do some of this work — surveying the pipeline from the air and inspecting it more closely in the areas that can be easily accessed by roads — but the bulk of it is done by mechanical “pigs,” sensor-laden robots that travel inside the pipeline looking for flaws.

A simpler process might involve outfitting remote stretches of the pipeline with sensors that would automatically radio a warning of impending problems. But the need to periodically change the batteries on such sensors lessens the appeal of that option. For electronic devices in remote or inaccessible situations like this, including environmental or mechanical monitoring sensors as well as some kinds of biomedical monitors, it can be inconvenient or even impossible to replace batteries.

Self-powered sensors

Harvesting electricity from small temperature differences could enable a new generation of electronic devices that don’t need batteries

It can be inconvenient to replace batteries in devices that need to work over long periods of time. Doctors might have to get beneath a patient’s skin to replace batteries for implanted biomedical monitoring or treatment systems. Batteries used in devices that monitor machinery, infrastructure or industrial installations may be crammed into hard-to-reach nooks or distributed over wide areas that are often difficult to access.

But new technology being developed by MIT researchers could make such replacements unnecessary.

Soon, such devices could be powered just by differences in temperature between the body (or another warm object) and the surrounding air, eliminating or reducing the need for a battery. They would use new energy-scavenging systems being developed by Anantha Chandrakasan, MIT’s Joseph F. and Nancy P. Keithley Professor of Electrical Engineering and director of the MIT Microsystems Technology Laboratories, and Yogesh Ramadass SM ’06, PhD ’09.

Chandrakasan honored for semiconductor work

Anantha Chandrakasan, director of MIT's Microsystems Technology Laboratories, today received the Semiconductor Industry Association (SIA) University Researcher Award.

Chandrakasan, the Joseph F. and Nancy P. Keithley Professor of Electrical Engineering, was honored for his work in micro-power design, wireless micro-sensor arrays and ultra-wideband radios.

Chandrakasan recently completed a joint project with Texas Instruments to design a micro-controller that uses only one-tenth the power compared to a conventional device. His group has also recently demonstrated ultra-low-power video architectures, energy-efficient ultra-wideband wireless circuits, energy scavenging systems and a sensor system using carbon nanotubes.

ISSCC: MIT energy scavenging circuit for piezoelectric power sources

MIT has pulled out all the stops in an energy scavenging circuit for piezoelectric power sources

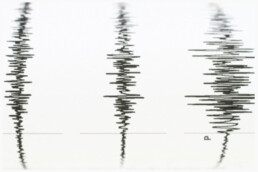

The traditional way to extract power from these is simply to connect a bridge rectifier to the piezo generator, followed by a reservoir capacitor.

However, a piezo generator is effectively an AC current source in parallel with a capacitor, so on every half cycle the current source wastes energy discharging the internal capacitance, then charging it to the opposite polarity.

Described at ISSCC (International Solid-State Circuits Conference) in San Francisco this week, MIT retains the rectifier and reservoir, but switches an inductor across the piezoelectric generator output.

Cyborg Moth Gets a New Radio

Research reported this week advances the goal of turning insects into unmanned aerial vehicles

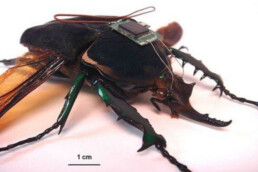

Attempts by the U.S. Defense Advanced Research Projects Agency (DARPA) to create cybernetic insects (hybrids of biological and electronic bugs) have yielded ultralow-power radios to control the bugs’ flight and a method of powering those circuits by harvesting energy, according to research that will be reported this week at the IEEE International Solid-State Circuits Conference (ISSCC)

Two papers being presented at ISSCC reveal the latest initiatives in the DARPA-sponsored Hybrid Insect Micro-Electro-Mechanical Systems (HI-MEMS) project, which is currently in its third year. The program’s goal is the creation of moths or other insects that have electronic controls implanted inside them, allowing them to be controlled by a remote operator. The animal-machine hybrid will transmit data from mounted sensors, which might include low-grade video and microphones for surveillance or gas sensors for natural-disaster reconnaissance. To get to that end point, HI-MEMS is following three separate tracks: growing MEMS-insect hybrids, developing steering electronics for the insects, and finding ways to harvest energy from the them to power the cybernetics.

Team develops energy-efficient microchip

Could lead to longer-lasting, self-charging cell phones, more

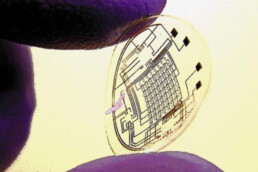

Researchers at MIT and Texas Instruments have unveiled a new chip design for portable electronics that can be up to 10 times more energy-efficient than present technology. The design could lead to cell phones, implantable medical devices and sensors that last far longer when running from a battery.

The innovative design is being presented Feb. 5 at the International Solid-State Circuits Conference in San Francisco by Joyce Kwong, a graduate student in MIT's Department of Electrical Engineering and Computer Science (EECS).

Reinventing the Transistor

Operating transistors at half steam could help squeeze more out of batteries.

As more and more functions are crammed into cell phones and other portable electronic devices, the capacity of their batteries is being sorely tested. To meet this challenge, Finnish handset manufacturer Nokia is turning to a novel approach in chip design that could slash the energy consumption of chips tenfold.

The technique involves the operation of chip transistors at voltage levels below the thresholds they normally need to switch on and off. In effect, this permits idle transistors or those performing low-performance functions to be placed in a kind of standby mode.

“In computer design, power consumption is getting to be a major driving force,” says Jamey Hicks, director of the Nokia Research Center in Cambridge, MA. This is particularly the case with mobile or embedded devices, he says: “The limit on the size of the device gives us a limit on the total energy budget.”

Chandrakasan to lead microsystems lab

Anantha Chandrakasan, the Joseph F. and Nancy P. Keithley Professor of Electrical Engineering, has been appointed director of MIT's Microsystems Technology Laboratories, effective Sept. 1, Dean of Engineering Thomas Magnanti announced this week.

"Anantha has broad interests that span many aspects of MTL's research portfolio. In particular, he is a pioneer in the area of ultra-low power integrated circuits and systems design for application in fields ranging from sensor networks to ultrawideband (UWB) radio," Magnanti said.

The Microsystems Technology Laboratories carry out research activities in the fabrication of extremely fine structures and their applications for integrated systems, including X-ray lenses, VLSI circuits and micro-gas turbine engines. These artificial microstructures in micron, submicron and nanometer scales are at the heart of the information revolution and of the newer fields of microsensors and actuators.

"Low-power CMOS digital design" is the second most frequently cited in the history of the JSSC (PDF)

“Low-power CMOS digital design” by A. P. Chandrakasan, S. Sheng, and R. W. Brodersen originally appeared in April 1992. It is the second most frequently cited in the history of JSSC and is still the most recent paper of any frequently cited from JSSC. (Requires subscription to access.)